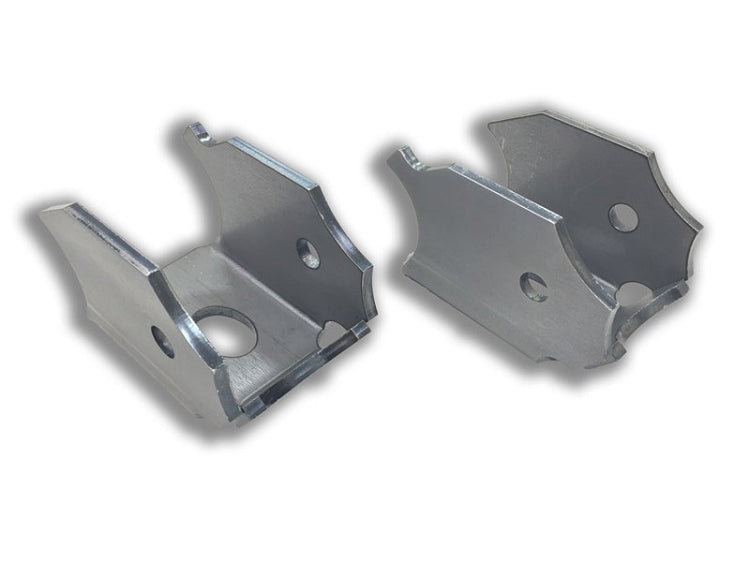

Jeep JK Lower Control Arm Brackets (pair)

- 2.625" mounting width fits common sized cartridge joints and factory control arm bushings

- Integrated skid plate

- Joint protection from direct impact

- Decreases premature wear on joint

- Designed to not interfere with joint movement

- Secured to axle better than OEM so it doesn’t rip off

- 1/4" thick steel

- Boxed plate for strength and impact resistance

- Shock Mounts are at factory height and do not limit your up-travel

- Sold in a pair

Off-roading is all about adventure, but bent and mangled factory lower control arm brackets can quickly spoil the fun. Artec’s Heavy Duty Brackets provide a reliable replacement that ensures you’ll never have to worry about bracket damage again. Unlike standard factory brackets, ours are specifically designed to improve functionality. Enjoy the thrill of the off-road without worrying about equipment failure.

Reviews

Install Instructions

Warning: This Part

Requires Fabrication Skills (Cutting, Grinding,

Welding) If you are not confident in your abilities Please have this

product installed at a Local Off-Road Shop .

Tools Required:

Safety Glasses, Gloves, Wrench set, Socket

Set, Torque wrench, Jack, Jack stands(Tall and short) , Wheel

chock, Cutting Tool(s)(Angle Grinder with cutting and flap disk , Sawzall,

Plasma cutter, Cutting torch) and Welder.

Step 1:

Take an inventory of your parts, If you are missing any parts Please contact Artec

Industries Immediately @ (855) 278-3299 M-F 8:30am-5pm MST

Step 2:

Break free the lug nuts on the front of the

Jeep (Do not completely loosen

or remove the lugnuts!)

Place wheel chocks at the rear wheels of the

vehicle. Jack up the front of the Jeep as high as you can

place the jack stands securely under the frame of the Jeep and under the axle.

Now lower the jack.

Step 3:

Remove lug nuts and the front wheels to

provide more working space .

Step 4:

Remove the lower control arm from the axle .

Step 5:

With the lower control arm removed use a your

cutting tool of choice to remove the lower control arm bracket off of the axle

and grind the surface smooth with an angle grinder using a flap disk to ensure

it is clean and ready for welding .

Step6:

Control arm bracket

orientation :

JK4412-2 is driver side JK4412-1

Passenger side

Step 7:

Place the Corresponding control arm bracket

under the axle Rotate it up So the Tab

will be level with the bottom flange of the coil bucket and slide it over until

you Have a ½” gap between the inside edge of the Lower control arm bracket

and the outside of edge of the coil

bucket. Once you have the bracket in

that position weld into place.

Step 8:

Paint brackets with a self-etching primer and

paint

Step 9:

Reinstall the Lower control arms do not fully

tighten the control arm bolts yet

Step 10:

Install tires and lugnuts (Do not fully tighten lug nuts)

Step 11:

Use a Jack to raise the Jeep off of the Jack

stands and remove them from under the vehicle then lower the Jack .

Step 12:

Torque the Lug nuts to Manufacturer Spec, Torque

Lca bolts

If you have Aftermarket control

arms refer to their manufacturers spec

After 50 miles check all bolts for tightness

and torque if needed.

Community Discussion