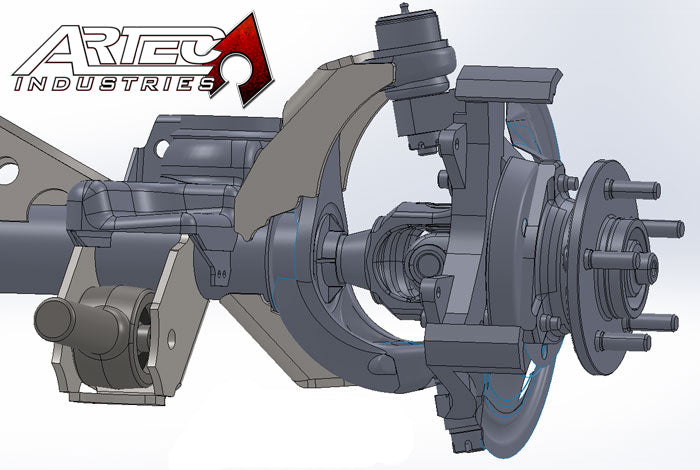

Inner C Gussets

- Precision fit that wraps around axle inner C not just adds a flat gusset

- Contoured inner C gusset adds reinforcement

- CNC laser cut and CNC bent for precise fit

- Engineered using 3D scan files

- Made in the USA

- JK made from ¼” Steel

- JL & JT made from 3/16” Steel

- *Requires welding

Artec’s Heavy Duty Inner C Gussets reinforce your front Dana 30 or 44 Jeep inner C’s, taking on serious off-road use. Made from precision-cut 3/16” thick steel, they contour perfectly to your inner c, providing essential rigidity and reinforcement to an area that’s prone to damage and flexing. Upgrade your adventure rig with Artec’s durable, precision-engineered solutions.

Notes : This kit requires general welding and fabrication skills. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

Reviews

Install Instructions

The installation of this product Requires

Welding, Fabrication, and Mechanical skills. You will need to remove the axle

from the vehicle to perform this Job. If

you are not confident in your abilities Please have this product installed at

an Off-road Shop.

Tools Required:

Safety glasses, socket set, wrenches, torque wrench, Needle

nose Pliers, Drift Punch set, tie rod separator, ball joint separator, Bungee

cords, Ball joint press, grinder or wire wheel, Welder, Welding PPE, Jack, Tall Jack stands.

Step 1:

Inventory all parts to ensure you have all of the correct pieces.

If you are

missing parts Contact Artec Industries Immediately at (855) 278-3299 M-F 8:30-5pm MST If outside of those hours

Email us at Sales@Artecindustries.com (Please

include picture of part number label on box as well as your invoice number)

Step 2:

Loosen the front lug nuts.

(Do not fully remove them, Just break them free.)

Step 3:

Secure and properly block the rear tires of vehicle on a

level surface .

Jack up front of vehicle and install jack stands under frame

behind the lower link brackets. and keep a jack under the axle.

Step 4:

Remove wheels from vehicle,

Remove front drive shaft from the axle ,

Remove the brake calipers and rotors (Set the rotors on a flat surface

so they do not warp), Hang the calipers

from the body with some bungee cords (Do not let the calipers hang freely from

the brake lines this can damage them.)

Step 5:

Remove the hub/axle shaft from Jeep as a unit With the hubs and axle shafts removed stuff

some rags in axle tubes.

(You can use a 36mm socket an remove

the axle shaft from hub if you choose to)

Step 6:

Remove cotter pins on Tie rods, Then loosen the castle nuts. (Leave the castle nuts installed by a few threads ! ) Remove the Steering stabilizer , Grab your Tie rod Separator, wedge it between the knuckle and the base of the tie rod the hit on the end of the Tie rod separator with your Big Freaking Hammer until it pops loose. Repeat this on the other side. Remove the castle nuts and the Drag-link and tie rod should drop off the Jeep. Now Unbolt and remove the knuckles from the axle, Using your ball joint press remove the ball joints from your C’s

(Tip: If you have a small Map gas torch heat the Castle nuts and heat the knuckle some this will help break parts free in the rust belt states.)

Step 7:

Remove the coil spring retainers from the axle, Remove Shocks, sway bar end links, and Track

bar.

Step 8:

Using a jack lower slowly lower the axle to remove the coil

springs. Raise the axle back up and

place jack stands under the axle

Step 9:

Remove upper and lower control arms. Pull the axle out from under the vehicle for

more room to work.

Step 10:

Heat the knuckles to about 300-400 degrees and weld on the C

Gussets.

Wrap the C’s in a welding bracket and allow to cool slowly.

(The even part numbers are going to

be on the driver side, The odd part numbers

on the passenger side)

Step 11:

Apply a thin coat of grease onto your ball joints and Install

into the C’s .

(We have found if you Place your Ball Joints in freezer for a few hours

before you install it can help them shrink and go in easier.)

Step 12:

Place your coil spring on the spring bucket to verify it

fits around the C Gusset.

(In rare cases the coil spring may contact

the C gusset if it does make contact mark the location on the c gusset where it

makes contact then remove the spring and grind a small relief so the spring

clears.)

Step 13: Move the axle back under the Jeep and install the upper and lower control arms

(A drift punch can

help with align the bolt holes, Do not

fully tighten the bolts.)

Step 14:

Install the coil springs and retainers then Raise the axle onto

jack stands.

Step 15:

Install the track bar, shocks, and sway bar end links on to the axle

(Do not

fully tighten the bolts.)

Step 16:

Install the knuckles

on to the vehicle and install Tie rod onto the vehicle along with the steering

stabilizer.

Torque the Upper ball joint to 75ftlbs , Lower ball joint to

80ftlbs , Tie rod ends to 65ftlbs , Steering stabilizer to 55ftlbs

Step 17:

Remove the rags from

the axle tubes . Place some grease on

the splines of the axle shafts an carefully

slip the axle shafts and unit bearings into place .

Torque the hub bolts to 75ftlbs

(Make sure you support the axle shaft

as it passes into the housing and do not force it into place this could risk

damaging the axle seals )

Step 18:

Install the rotors and calipers onto the Jeep torque caliper

bolts to 11ftlbs . Then install the wheels and tires, tighten lug

nuts.

(Do not torque lug nuts yet)

Step 19:

Lower the Jeep off of the Jack stands and onto the ground. Once the Jeep is on its own weight.

Torque the lug nuts to 95ft lbs

Torque upper control arm to 55ftlbs

Torque Lower control arm to 85ftlbs

Torque Trackbar to 55ft lbs

Torque Shocks to 20ftlbs

Torque Swaybar links to 75ft

lbs.

After 50 Miles torque all bolts to their

proper specs

Community Discussion