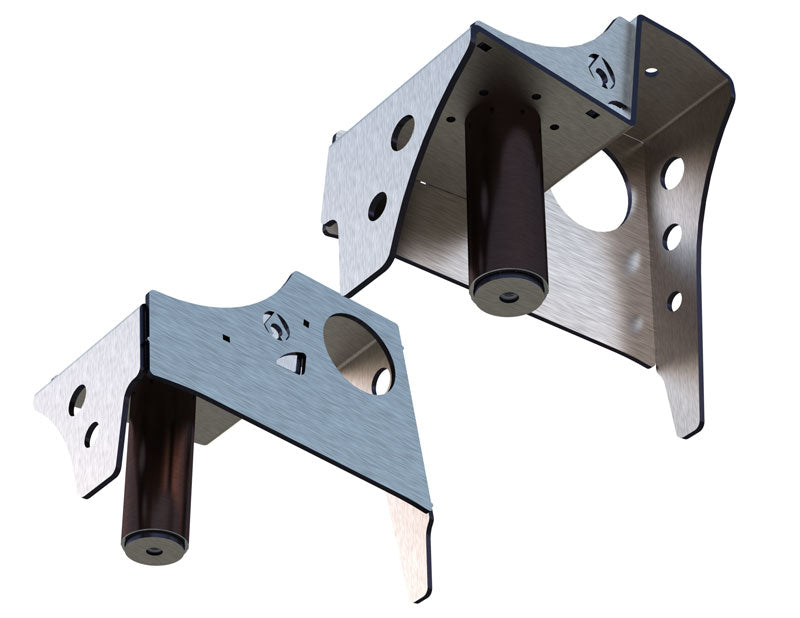

TJ Front Frame Coil Buckets for OEM bumpstops

- Made from 1/4" thick steel

- CNC laser cut and CNC bent for precise fit

- Engineered using 3D scan files

- Directly replace your factory bumpstop

- Utilizes OEM threading

- Easy Installation

- Gusseted between the coil bucket and shock mount for extra strength

- Includes a 2.0" OD piece of DOM tubing

- Choose factory or clevis style attachment for your shocks with this product

- TJ/LJ direct replacement, upgrade for leaf-sprung vehicles transitioning to coil spring suspension

- Made in the USA

- *Requires welding and painting.

Upgrade your vehicle suspension with Artec’s Heavy Duty Front Frame Side Coil Buckets. Made for those who want to build their suspension to their preference, these replacement coil buckets provide maximum strength and are easy to assemble. With laser-cut and CNC-bent pieces, this DIY kit is a breeze to install. Our design also complements the factory frame while providing a distinct look for off-road enthusiasts. Join the fusion of form and function with Artec Industries.

Notes : This kit requires general welding and fabrication skills. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

Reviews

Install Instructions

THIS PART REQUIRES WELDING AND GENERAL

FABRICATION SKILLS. ONLY COMPETENT WELDERS SHOULD ATTEMPT TO INSTALL THIS PART.

Tools Required :

Safety Glasses, Gloves, , Socket Set, Wrenches, Wheel

chocks, Cutting Tool of your choice

(Sawzall, Grinder, plasma, cutting torch), , , Lug wrench, Wheel Lock Key (If

you have wheel locks the guys at the tire shop probably lost the wheel lock

key), Map gas Torch (Optional but

probably Required in Rust Belt States)

Anti seize, Blue Loctite, Cutting oil, Welder/ Welding PPE,

Step 1:

Inventory that you have all of the parts for your order If you are missing

parts or have incorrect parts contact Artec Industries Immediately @

(855)-278-3299 M-F from 8am-5pm MST. If

it is after those hours please Email Sales@Artecindustries.com

Step 2:

Loosen the front lug

nuts. (Do not fully remove them, Just break them free.)

Step 3:

Secure and properly block the rear tires of vehicle on a

level surface .

Jack up front of vehicle and install jack stands under frame

behind the lower link brackets. and keep a jack under the axle Temporally.

Remove wheels from vehicle, Remove front

drive shaft from the axle , Remove the

brake calipers and rotors (Set the rotors on a flat surface so they do not

warp), Hang the calipers from the body

with some bungee cords (Do not let the calipers hang

freely from the brake lines this can damage them.)

Step: 4

Remove the coil spring retainers from the axle, Completely remove the Shocks the vehicle and Remove, sway bar end

links, and Track bar from axle side of vehicle .

Step 5:

Using a jack lower slowly lower the axle to remove the coil

springs. Raise the axle back up and

place jack stands under the axle.

Step 6:

Using a tape measure from front of frame to center of coil

mount and center of shock mount record

those measurements for later.

Step 7:

Remove the rubber splash guard from the lower portion inside

of the fender wells, Once the rubber liners are removed you will want to unclip

and move any lines or harnesses that are around the mounts to ensure they are

protected and do not get cut or damaged . (You can

remove the front fenders from the vehicle for more room to work if you would

like but it is not needed. )

Step 8:

Cut off the existing shock/coil mount from the vehicle and

grind the area smooth to ensure it is free of any debris, paint, or rust so it is prepped for welding

Step 9:

Open the Bag with the small disk and set them out , You will take the 2 smallest disk with the

hole bored into th center and weld the supplied nut to the center of those

parts. Then Weld those disk to the

bottom of the long tube with the nut from the disk on the inside of the tube

the rest of the round disk can be set aside for later.

Step 10:

You will want to stand the main bracket upright so the front

and back legs are contacting the bench. (Use welding magnets to help) Slip the long tube through the hole on the

top of the coil mount. (The opening on the coil mount may need to be cleaned up

with a file to get the tube to slip into place.) The long tube should be contacting the bench

and you should have roughly 1/2" of tube sticking up through the top of

the main part of the coil mount. Take

the TJ2002-5 (large disk with large hole cut out ) slip this overtop of the where it protrudes out of the top of the coil

mount and weld it to the top of the coil mount and weld the tube to the disk as

well. Then take the small solid disk and weld it to the top of the tube.

Step 11:

Place the TJ2002-3 (large side plates) onto the tabs on

the coil mounts and tack weld into position

Now take the small gusset

an tack weld it in position on the coil tower once both brackets are

tacked into place you can fully weld them to the coil tower.

Step12 :

Using the

measurements you have previously taken

center the coil mount and shock mount as much as you can and weld into

place on the frame . Once the welding is

completed and parts have cooled spray with Primer and Paint to keep parts from

rusting .

Step 13:

Remove the factory bump stop cup and bump stop cup from the Jeeps OEM coil

bucket and bolt it onto the tube on the TJ2002 shock tower. Re install the Rubber inner fender liner

into the fenders .

Now Using a jack raise the axle off of the jack stands and

remove them temporarily to lower the axle and insert the coil springs then

raise the axle back up onto the Jack stands .

With the axle supported reinstall the coil spring retainers.

Step 14:

Install the Shocks,

Track bar, Sway bar end links onto the vehicle .

Install the rotors and calipers onto the Jeep torque caliper

bolts to 11ftlbs . Then install the

wheels and tires, tighten lug nuts.

Step 15:

Lower the Jeep off of the Jack stands and onto the

ground. Once the Jeep is on its own

weight.

Torque the lug nuts to 95ft lbs

Torque Track bar to 55ft lbs

Torque Shocks to 20ftlbs

Torque Sway bar links to 75ft lbs.

After 50 Miles torque all bolts to their

proper specs

Community Discussion