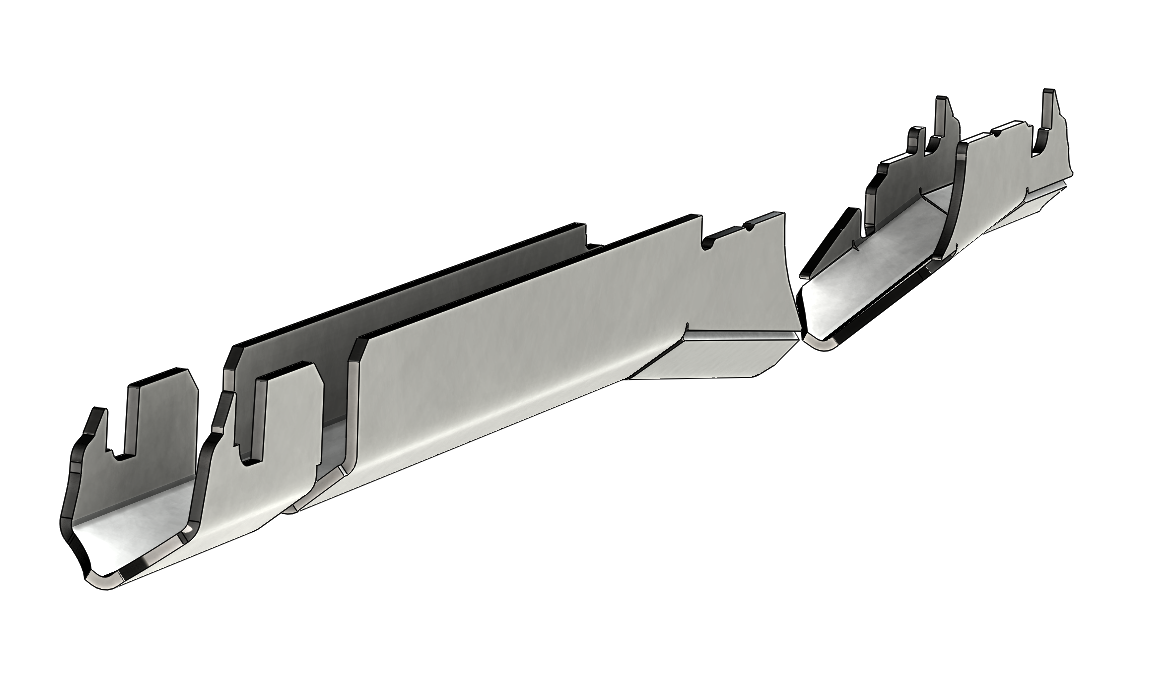

Ford SuperDuty Front Axle Lower Truss

- 1/4" thick mild steel precision CNC designed, cut and bent for great fitment

- No loss of ground clearance under the cast differential

- Bottom triangle shape provides increased structural rigidity and helps axle skid over obstacles

- Truss spans entire length of axle for complete reinforcement of the axle tubes

- Great for individuals who like to drive fast and jump their vehicles

- Comes in 5 separate pieces for compact shipping and easier installation

- Made in the USA

Artec Industries' Superduty Lower Truss reinforces the entire front axle on Ford F-250 and F-350 for maximum up-travel and no loss of ground clearance. Designed for heavy engine use and great for mud and dune enthusiasts. CNC cut and formed to fit great on your axle with little-to-no modifications required.

Reviews

Install Instructions

Warning:

This Part Requires General

Mechanical Abilities If you are not

confident in your abilities Please have this product installed at a Local

Off-Road Shop .

Tools Required:

Safety Glasses, Gloves, Wrench set, Socket Set, Torque

wrench, , Tie rod separator, Jack, Jack

stands(Tall and short) , Wheel chock,, Cutting tool (sawzall , cutoff

wheel, plasma cutter ect...) Welder and welding ppe.

Step 1:

Take an inventory of your parts, If you are missing any parts Please contact Artec Industries

Immediately @ (855) 278-3299 M-F

8:30am-5pm MST if it is after those hours please email us pictures of what you

received , along with product labels on the box and packing slip at Sales@artecindustries.com

Step 2:

Place Wheel chocks at the rear wheels on the vehicle. with the vehicle on the ground break the lug

nuts on the wheels free (Do not fully loosen or remove

them.) Using a jack raise up the

front of the vehicle and place tall jack stands under the frame behind the

lower control arm mounts. and a shorter

set under the axle.

Step 3:

Remove wheels from vehicle,

Remove front drive shaft from the axle ,

Remove the brake calipers and rotors (Set the

rotors on a flat surface so they do not warp), Hang the calipers from the body with some

bungee cords (Do not let the calipers hang freely from

the brake lines this can damage them.) Remove cotter pins on Tie

rods, Then loosen the castle nuts. (Leave the castle

nuts installed by a few threads ! ) Remove

the Steering stabilizer , Grab your Tie

rod Separator, wedge it between the knuckle and the base of the tie rod the hit on the end of the Tie rod separator

with your Big Freaking Hammer until it pops loose. Repeat this on the other

side. Remove the castle nuts and the Drag-link and tie rod should drop off the

vehicle.

Step 4:

Remove the coil spring retainers from the axle, Remove Shocks, sway bar end links, and Track

bar.

Using a jack lower slowly lower the axle to remove the coil

springs. Raise the axle back up and

place jack stands under the axle, Remove upper and lower control arms. Pull the axle out from under the vehicle for

more room to work.

Step 5:

Clean the axle tubes of any paint, rust, and debris to prep

for welding.

Step 6:

Place part tr6005-5 under the Passenger Side tube between

the Lower control arm mount and the C for the knuckle and tack weld into

place.

Step 7:

Place tr6005-1 on the

driver side Axle tube between the differential and C for the knuckle. and Tack

weld into place

Step 8:

Place tr6005-2 on the

axle tube between the diff housing and control arm bracket on the passenger

side

and tack weld into place

Step 9:

Tack weld part Tr6005-4 in the opening on the tr6005-1 and

tack weld into place .

Step 10:

Tack weld part Tr6005-3 in the opening on Tr6005-2 and the

housing.

Step 11:

Stitch weld all of the Truss Pieces to the axle tubes and

housing Move around from 1 end to the

other and work your way around the axle to keep the heat down to minimize the

risk of warping the axle . After the truss is welded on the axle Prime and paint the axle.

Step 12:

Reinstall the axle into the vehicle and torque all bolts to factory specs .

After 50 miles Check all bolts for tightness and tighten if

needed .

Community Discussion