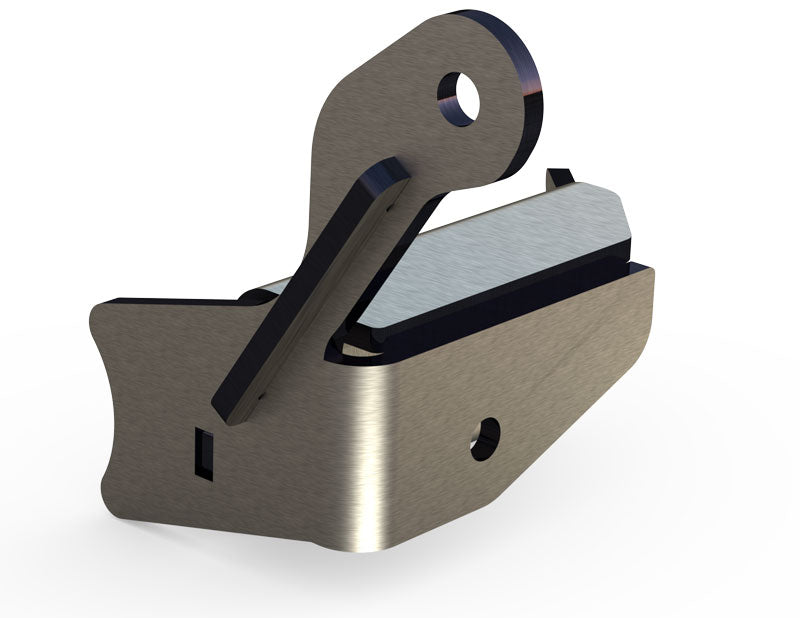

Stock Trackbar Bracket Replacement for TJ Front Axle

- 1/4" steel

- CNC laser cut and CNC bent for precise fit

- Engineered using 3D scan files

- Replaces factory bracket

- Improved ground clearance

- Made in the USA

This heavy bracket is designed to replace the weak factory trackbar bracket on the front 30 and Rubicon 44 axles in the Jeep TJ, LJ, XJ, and ZJ. The factory bracket often has a wallowed out hole allowing axle shifting and is one of the major contributors to the feared DEATH WOBBLE. This bracket replaces the factory bracket for better piece of mind. The 1/4" thick CNC precision cut and formed components of this setup ensure a quality, heavy duty solution.

Notes : This kit requires general welding and fabrication skills. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

Reviews

Install Instructions

THIS PART REQUIRES WELDING AND GENERAL

FABRICATION SKILLS. ONLY COMPETENT WELDERS SHOULD ATTEMPT TO INSTALL THIS PART.

Tools Required :

Safety Glasses, Gloves, , Socket Set, Wrenches, Wheel

chocks, Cutting Tool of your choice

(Sawzall, Grinder, plasma, cutting torch) Tie rod separator, Needle Nose

Pliers, Large Hammer, Lug wrench, Wheel Lock Key (If you have wheel locks the

guys at the tire shop probably lost the wheel lock key), Map gas Torch

(Optional but probably Required in Rust

Belt States) Anti seize, Blue Loctite,

Cutting oil, Welder/ Welding PPE.

Step 1:

Inventory that you have all of the parts for your order If you are missing

parts or have incorrect parts contact Artec Industries Immediately @

(855)-278-3299 M-F from 8am-5pm MST. If

it is after those hours please Email Sales@Artecindustries.com

Step 2:

Place wheel chocks at the rear wheels of the vehicle. Break free lug nuts on rear wheels. (Do not fully loosen or remove lug nuts yet.)

Step 3:

Jack up the front of the vehicle and set the axle on Jack

stands.

Step 4:

Remove the front wheels from the vehicle, An set to the

side.

Step 5:

Remove the steering stabilizer from the vehicle , remove the

passenger side sway bar end link, Remove cotter pins on Tie rod ends and drag

link, Then loosen the castle nuts. (Leave the castle nuts installed by a few threads ! ) Grab your Tie rod Separator, wedge it

between the knuckle and the base of the tie rod Hit on the end of the Tie rod

separator with your Big Freaking Hammer until it pops loose Then repeat on the

other side and with drag link . Remove

the castle nuts and the Drag-link and tie rod should drop off the Vehicle.

( Tip : If you have a small Map gas

torch heat the Castle nuts and heat the

knuckle some this will help break parts free in the rust belt states )

Step 6:

With the Steering removed from the vehicle no remove the

track bar from the vehicle. Now you can

cut off the factory track bar mount on and sway bar bracket on the Passenger

side of the axle .

Step 7:

Prep the axle the axle for welding by removing and paint/

rust. in the area from the C for the knuckle over 9 inches .

Step 8:

Tack weld TJ2016-3 to the TJ 2016-2 . Slip the TJ2016- 1 tab into the TJ2016-2

keyed slot (for proper orientation the Artec logo that is laser etched will be

facing up on the TJ2016-1 . Insert your

track bar into position on the mount and bolt then tack weld the TJ2016-2 and

TJ2016 together to set the mounting width

. Then remove the track bar from

the bracket and fully weld the bracket together.

Step 9:

Roll the TJ2016 Track bar mount into position on the axle,

The top of the bracket will contact the

bottom of the coil spring mount and the inside of the sway bar mount will

contact the side of the coil spring mount.

With the track bar mount in position fully weld it into place .

Step 10:

Clean the part of any machining oil, Prime and Paint the

part and bare areas on the axle.

Step 11:

Install the track bar into the vehicle, Install Passenger

side Sway bar end link. Then reinstall the steering on the vehicle . Now install the wheels. (Do not fully tighten all of the bolts yet) Jack up the vehicle and remove the jack

stands so you can lower vehicle onto the ground. With the vehicle on the ground

tighten all of the bolts and torque the lug nuts.

Step 12:

Take the vehicle to an alignment shop to have an alignment

performed to ensure everything is in spec.

Check all bolts for tightness after 50 miles

.

Community Discussion