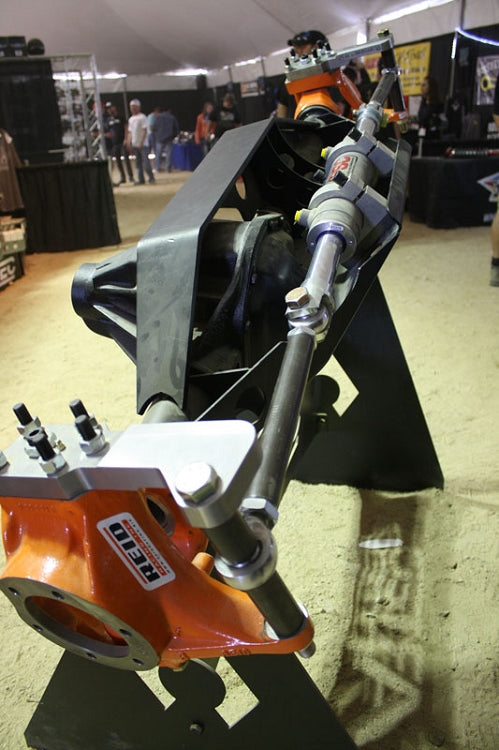

60 FORD Front Ram Mount & Truss '78-79

- Correctly angled to account for Dodge knuckles

- 3/8" thick truss top & 1/4" thick ram mount/gussets; CNC cut and bent for precision fit

- Low profile truss allows ideal geometry for link joints

- Complete axle tube reinforcement, not just for mounting links

- Interlocked 1/4" gussets for easy assembly and maximum strength

- 1/4" bridge connects truss to ram mount for extra protection

- Drainage holes in ram mount and gussets for easy cleaning and reduced weight

- Ram mount doubles as axle skid plate for protection against bending and shearing

- Additional bolt-on skid plate for easy gear removal

- Fits both PSC Motorsports and Howe Performance double-ended hydraulic rams

- Clearanced for rotated knuckles and pinions

- Optional gusset for welding removable skid plate to aftermarket differential cover

- Overall low-profile design for easier fitment and less interference with vehicle components

- Made in the USA

Artec Industries presents the Dodge Front 60 Hydraulic Ram Mount and Truss, a heavy-duty truss system that ensures the protection of your steering components. The ram mount's unique design places it in its most effective and strongest location, near the axle centerline and away from the rocks. The skidplate, integrated with the mount, provides further protection from rocks. Compatible with PSC Motorsports and Howe Performance double-ended hydraulic rams, the truss system reinforces the axle against bending and shearing while providing a location for mounting your 3 and 4 links. The truss and ram mount work together to reinforce each other in every direction.

Reviews

Install Instructions

THIS KIT INVOLVES EXTENSIVE WELDING AND

GENERAL FABRICATION SKILLS. ONLY COMPETENT WELDERS SHOULD ATTEMPT TO INSTALL

THIS KIT.

Tools Required :

Safety Glasses, Gloves, Tape Measure, Socket Set, Wrenches,

Wheel chocks, Jack, Jack stand. Cutting

Tool of your choice (Sawzall, Grinder, plasma, cutting torch) Welder.

Step 1:

Inventory that you have all of the parts for your order If you are missing

parts or have incorrect parts contact Artec Industries Immediately @

(855)-278-3299 M-F from 8am-5pm MST If it is after those hours please Email

Sales@Artecindustries.com

Step 2:

Place wheel chocks at the rear wheels of the vehicle. Break free lug nuts on front wheels (Do not fully loosen or remove lug nuts yet.)

Step 3:

With the vehicle sitting on the ground, Measure your ride

height at the frame and height of the centerline of the axle, Also take

measurement of your wheel base.

(Make a note of this for later.)

Step 4:

Jack up the front of the vehicle and set the axle on Jack

stands, Remove the front wheels from the vehicle, With the wheels removed Jack the vehicle up

again. Securely place tall jack stands

under the frame behind the LCA or Leaf

spring mounts at the previously measurement of ride height. Place a 2nd sent of

jack stands under the front axle.

Step 5:

Remove the existing front axle from the vehicle.

Step 6:

Prep axle the truss will be welded onto by removing all

mounts and paint/ rust. Once the axle is

prepped. Slide new axle under the vehicle and place on jack stands at the

measurement of what the centerline height was at ride height also make sure it is

set to the wheelbase you will be using.

Step 7:

Using another jack stand or block of wood set under the

Pinion of the axle, Set the Caster angle and pinion to desired angle of your build to ensure it

does not get changed . Now place the truss on top of the axle so it is level

with the ground and not tilted forward or backward (If your truss is angled it can cause upper arm

mounts or the truss to twist off under load) You may need to trim some gussets on the

truss to allow it to sit level depending on your wheelbase and pinion angle. (Ford

9” trusses will need to be trimmed to fit your axle)

Step 8:

With the truss set level on top of the axle tack weld The

truss ends to the axle tubes.

Step 9:

With the truss tacked into place Pull the axle from under

the vehicle to allow more space for welding.

Once the axle is pulled from under the vehicle. Heat the axle to about 400 degrees Start

to weld the gussets to the axle and

truss .When welding, Start on one side of the axle, Weld a small amount, Then

move on to the opposite side of the axle to allow each side to cool. This will

help prevent warping .Stitch welding is preferred and welding every inch of every seam is not

necessary. Grind and clean the rosette welds on the axle. (Optional) Stitch weld the axle tubes to the ends of the casting for

added axle strength and to prevent the axle tubes from twisting. If your

truss has a Ram mount you will place the ram mount on the axle and roll it up

into place until the ram mount contacts the gussets and weld it into place. you

will want to mount your steering ram to the mounting blocks and center the ram

as much as possible you may only be able to run 3 of the mounts to center the

ram. with the ram at full lock and

knuckle in full lock you will want to weld the mounting blocks into position so

the Ram's shaft and tie rod are inline (if they are not

inline it could cause stress to the shaft

and damage the ram) . If

you have any Control arm mounts, Shock mounts, Coil over tabs, Track bar mounts

that need to be welded on to the axle

you will need to place the axle under the vehicle on jack stands at ride

height and desired wheelbase an weld them on at this time in their proper

location for your specific build. Once

all of the welding is complete you will

wrap the axle in a welding blanket to slowly cool overnight.

Step 10:

Clean the Truss and axle of any machining oils and Prep for

paint or powder coat.

Step 11:

Install the axle back under the vehicle and place on jack

stands. Install the wheels on the vehicle and tighten the lug nuts (Do not torque them down yet.) Lift the vehicle and remove all of

the jack stands and set the vehicle on the ground. with the vehicle on the ground check all of

the bolts and lug nuts are torqued to proper specs. we recommend drawing a line

on the nut and bolt heads and where they are mounted for quick reference when

checking for tightness after 50 miles .

Community Discussion