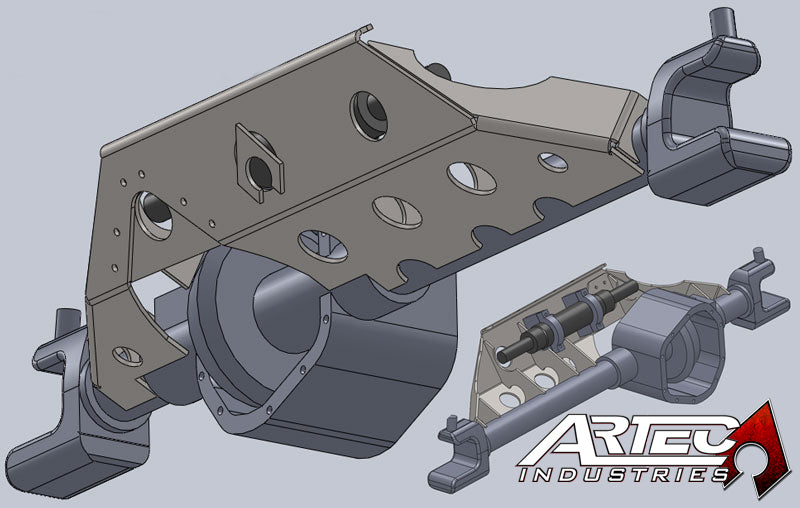

60 Full Hydro Ram Mount (No Truss)

- 1/4" mild steel ram mount and gussets

- CNC laser cut and CNC bent for precise fit

- Engineered using 3D scan files

- Drainage holes for easy cleaning and reduced weight

- Protect your ram, tie rods, and reinforce your Axle with Artec’s Ram Mount skid plate.

- Easy to service gears

- Flush surface hardware

- Fits most doubled ended hydraulic rams

Introducing Artec Industries' Hydraulic Ram Mount - the ultimate solution for protecting your vehicle's steering system. Our heavy-duty mount is designed to endure extreme abuse and safeguard your vital and expensive steering components. With a unique placement near the Axle center line and an integrated 1/4" thick skid plate, it's built to withstand rocky terrains. Compatible with most double-ended hydraulic rams and designed to work seamlessly, it provides the strongest hydraulic steering solution available. Our gusseting design reinforces the mount to resist impact damage, while the end-to-end Axle tube extension reinforces the Axle against bending and shearing. *RM6005 Dodge Ram Mount is intended to be used with the Passenger Side Drop Dodge KingPin Axles. *Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

*RM6005 is for Passenger Drop KingPin Dodge 60.

Reviews

Install Instructions

THIS KIT INVOLVES EXTENSIVE WELDING AND GENERAL

FABRICATION SKILLS. ONLY COMPETENT WELDERS SHOULD ATTEMPT TO INSTALL THIS KIT.

Tools Required :

Safety Glasses, Gloves, , Socket Set,

Wrenches, Wheel chocks, Jack, Jack stand. Cutting Tool of your

choice (Sawzall, Grinder, plasma, cutting torch) Welder.

Step 1:

Inventory that you have all of the parts for

your order If you are missing parts

or have incorrect parts contact Artec Industries Immediately @

(855)-278-3299 M-F from 8am-5pm MST If it is after

those hours please Email Sales@Artecindustries.com

Step 2:

Place wheel chocks at the rear wheels of the

vehicle. Break free lug nuts on front wheels (Do not fully loosen or remove lug nuts yet.)

Step 3:

Jack up the front of the vehicle and set the

axle on Jack stands, Remove the front wheels from the vehicle, With

the wheels removed Jack the vehicle up again. Securely place tall

jack stands under the frame behind the LCA or Leaf spring mounts at

the previously measurement of ride height. Place a 2nd sent of jack stands

under the front axle.

Step 4:

Prep axle To weld the Ram mount into place. Once

the axle is prepped.

Step 5:

You will want to

mock fitment of the ram mount against the axle ,Mount your steering ram to the mounting blocks centering the ram

as much as possible on the ram mount. (You

may only be able to run 2 or 3 of the mounts to center the ram.) With

the ram at full lock and knuckle in full lock you will want to Tack weld the Ram

Mount and Ram mounting blocks into position so the Ram's shaft and tie rod are

inline (If they are not inline it could cause stress to the shaft and damage the ram You will also want to

protect the ram’s shaft from weld splatter this could damage the ram ) With the ram mount tacked into place ,Pull the

axle from under the vehicle to allow more space for

welding. Once the axle is pulled from under the vehicle.

Remove the Ram from the ram mount. Heat the axle to about 400 degrees

Start to weld the gussets to the axle and ram mount .When welding,

Start on one side of the axle, Weld a small amount, Then move on to the

opposite side of the axle to allow each side to cool. This will help prevent

warping .Stitch welding is preferred and welding every inch of every

seam is not necessary. Grind and clean the rosette welds on the axle. (Optional) Stitch weld the axle tubes to the

ends of the casting for added axle strength and to prevent the axle tubes from

twisting. Once all of the

welding is complete you will wrap the axle in a welding blanket to

slowly cool overnight.

Step 6:

Clean the Ram mount and axle of any machining

oils and Prep for paint or powder coat.

Step 7:

Install the axle back under the vehicle, and place on jack stands. And install your ram

Install the wheels on the vehicle and

tighten the lug nuts (Do

not torque them down yet.) Lift the vehicle and remove all of the jack stands and set the

vehicle on the ground. with the vehicle on the ground check all of

the bolts and lug nuts are torqued to proper specs. we recommend drawing a line

on the nut and bolt heads and where they are mounted for quick reference when

checking for tightness after 50 miles .

Community Discussion