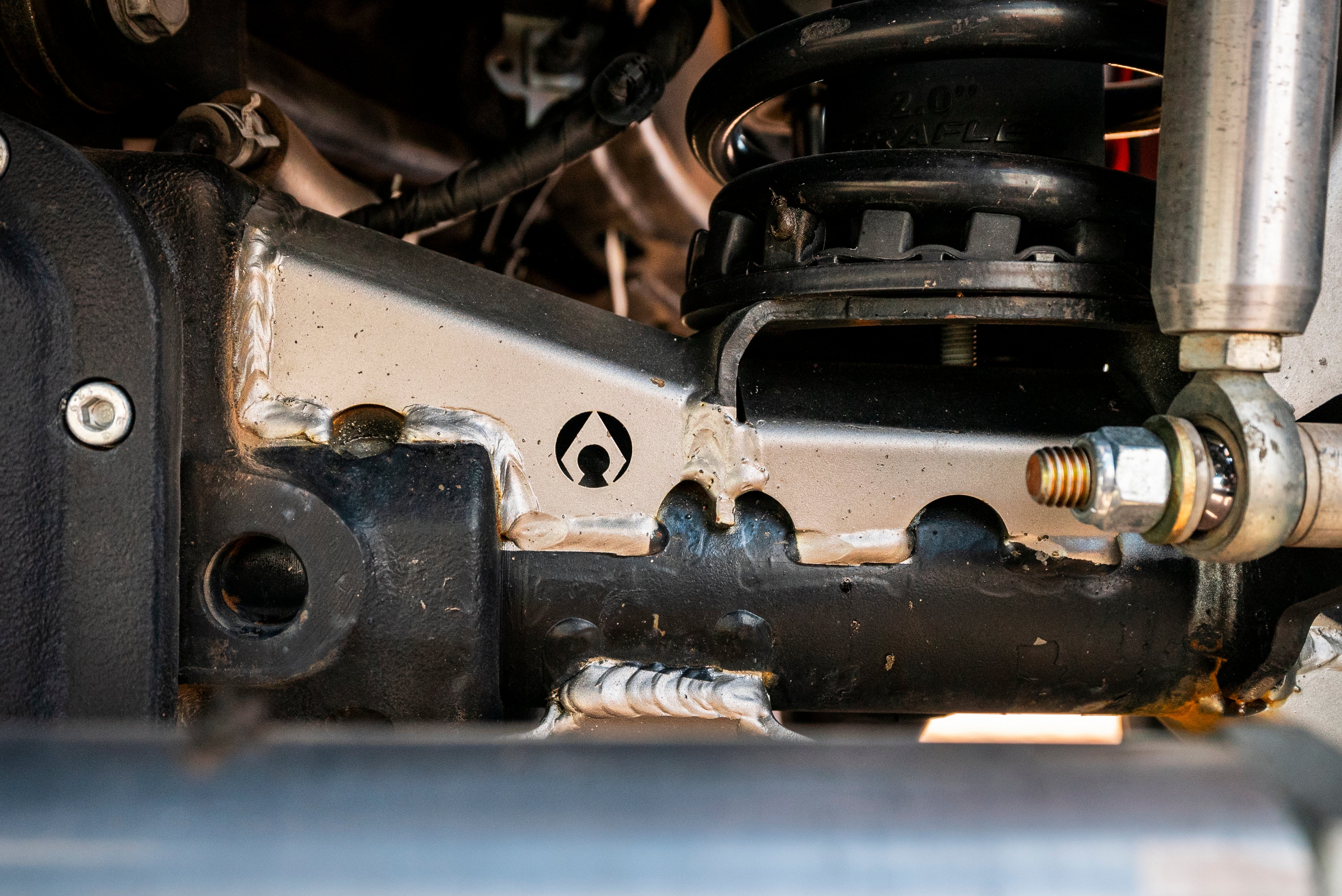

JL-JT APEX Front Axle ARMOR KIT

- Apex design provides more rigidity than a flat top truss design. PATENTED

- CNC precision laser cut

- Dimpled holes provide light weight and rigidity

- CNC precision bending ensures perfect fitment

- Hassle-free installation: Reinforced truss – simply drop it in place and start welding

- 3D models from Dana Corp and vehicle OEM for perfect fit and clearance.

- 70% less welding needed than previous designs for less warping, faster turnaround, lower costs

- Contours to both the cast steel differential and FAD (front Axle disconnect)

- Worry-free wheeling for multiple tire sizes on stock JL Axles

- Strengthens weak Front and Center Axle Disconnect (FAD/CAD) by bridging it.

- American Made

Artec Industries introduces the APEX Truss, a revolutionary Axle truss design that brings cost savings, strength, weight reduction, precision fitment, and complete Axle protection. The unique peaked shape top provides extra rigidity and eliminates long weld seams, making it easy to weld and quick to install. The APEX truss extends from end to end of the Axle and is suitable for both extreme applications and daily driving. It’s the ultimate low-cost solution for making your factory Jeep Axle stronger and more reliable. *Please note this kit is NOT for the newer 05 casting. If you have the 05 casting M210, you will need to buy part numbers JL4507, JL4508, and JL4504 to piece together your armor kit with the truss needed for your axle.

JL3110 - Use on JL Sport/Sahara

JL4510 - Use on JL Rubicon (US/Canada), JT Rubicon (All countries), Sport MaxTow

JL4511 - Use on JT Sport/Overland (US/Canada), JL Rubicon (Non-US/Canada)

NOTE: DOES NOT FIT EXTREME RECON OR MOJAVE GLADIATOR WITHOUT MODIFICATION. RECENTLY JEEP HAS ALSO SWITCHED TO A "COMMON" DIFFERENTIAL WHICH IS DIFFERENT THAN THE ORIGINALS. THIS TRUSS CAN BE MODIFIED TO FIT THIS NEWER DIFFERENTIAL.

*Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

**Stock axles have other components that may not hold up to the abuse of larger tires. Artec implies no guarantees that you will not break some component on your stock axles using larger tires. Use at you own risk.

***THIS KIT IS INTENDED FOR VEHICLES WITH AT LEAST MINOR LIFTS (1.5"+ RECOMMENDED) AND AT LEAST 1/2" BUMP STOP EXTENSIONS. CHECK CLEARANCES BEFORE INSTALLING. NOT TESTED IN NON-US JLs or RIGHT HAND DRIVE AXLES.**

NOTE: This kit requires general welding and fabrication skills including welding to the cast center section and cast inner c's. Welding should only be done by a competent welder. Artec Industries implies no guarantees or warranties and is not liable for improper installation.

*Some grinding and fitment may be required when installing this kit. Every axle varies slightly and some fabrication may be required.

** In rare and extreme cases, the truss may come into contact with oil pan. Prior to operating the vehicle, remove the coil springs, cycle the suspension including full compression of both sides simultaneously and add bumpstop extensions to prevent damage to oil pan.

*** Axle Armor kits will not work on Non OEM Jeep Axles Example : Dana/ Spicer Ultimate44 housings, Dynatrac Pro Rock44 axles, Or G2 D44 Axles ***

Reviews

Install Instructions

While we're working on the detailed instructions,

here's some tips on installing your APEX truss. Refer to online pictures for

orientation of the truss.

Warning:

Installing this product requires Welding and Fabrication skills, If you

are not confident in your abilities to complete this task please have this

installed at an qualified off-road shop .

Step 1:

Inventory all parts to ensure you have all of the correct

pieces. If you

are missing parts Contact Artec Industries Immediately at (855) 278-3299 M-F 8:30-5pm MST If outside of those hours

Email us at Sales@Artecindustries.com (Please include picture of part number

label on box as well as your invoice number

Per our Shipping service if box is damaged Keep all packaging if box is

damaged aswell as photograph the box to ensure any shipping claims can be

honored )

STEP 2.

Unpack contents of shipment. Remove axle from vehicle for

best results and easiest installation. Prior to mockup make sure axle is clean

and uninstall any oem and aftermarket bolt-on accessories that may conflict

with truss installation. Remove axle breather hose and uninstall any electric

locker wires from casting. This area will be welded so care should be taken to

prevent these components for melting.

STEP 3.

Using a marker or paint pen, indicate the areas on the axle

where the truss touches the axle to prepare for welding. Remove truss pieces

from axle. Using an angle grinder with either a flapper disc or wire wheel

brush, clean the surface of the axle tube, casting, upper control arm mount,

and coil perch until bare steel is exposed. Clean surfaces on drivers side

casting, tube, and coil perch in a similar fashion. Repeat step 2 and place all

truss pieces back on axle.

STEP 4.

Prior to welding, ensure that the bottoms of all the truss

pieces are in a straight line all together. The long truss can sag a little

near the UCA mount so push down on the part over the casting and it'll

straighten out. Place tack weld on truss pieces to hold all in place. Double

check all truss pieces are straight.

STEP 5.

Begin welding small strips of truss that touch the axle

tube. You want to move around to different parts of the axle as you weld so you

don't heat up areas too much. Place a welding blanket over welds so they do not

cool too quickly.

STEP 6.

To weld truss to cast section with best results, preheat

casting evenly around where truss contacts to approximately 400 degrees. DO NOT

HEAT UNTIL GLOWING RED AS THIS MAY DAMAGE THE CASTING. Once preheated, weld

truss to casting before it cools. For best results, use a needle scaler or

peening hammer to relieve the weld directly after welding. Post heat the area

to approximately the same temp you used to preheat. Wrap axle in a welding

blanket to slow the cooling process, the cooling should be slow (18-24hrs.) and

uniform. (The idea behind this method is to relieve the stresses in the

materials prior to welding, and ensure that the plate steel does not cool

quicker than the cast resulting in stress cracks.)

STEP 7.

When completely cooled, check for any cracks in weld

especially around the casting. If cracks are discovered repeat the necessary

steps above, grinding out any cracked welds and prepping the area.

STEP 8.

Remove the hub/axle

shaft from Jeep as a unit With the hubs

and axle shafts removed stuff some rags in axle tubes.

Remove the knuckles

from the Vehicle . Now Remove your ball

joints from the axle the Heat caused by welding the C gussets can damage the ball

joints. Once the ball joints are removed

weld the C gussets into place (The JL4405-3 is Driver

Upper JL4501 is Passenger side

upper The JL4505-2 is driver side lower

and Jl4405-4 is passenger side lower)

Then wrap in a blanket to cool slowly

Once the C's are cool you can Install the ball joints we suggest

freezing them before you install and apply a thin layer of grease to help

install them Once the Ball joints are

installed install the knuckles onto the axle and Remove the rags from the axle

tubes . Place some grease on the

splines of the axle shafts an carefully

slip the axle shafts and unit bearings into place . all of the knuckle and hub

bolts to factory specs.

(Make sure you support the axle

shaft as it passes into the housing and do not force it into place this could

risk damaging the axle seals )

STEP 9.

Use a grinder or wire wheel to clean the surface of the LCA

mounts to remove any paint, rust, or debris to ensure it is ready for welding .

STEP 10.

Place the Control arm skids on the LCA bracket and weld them

into place .Weld the open seam on the

LCA skid and leave the little round holes open for Mud and water to drain from.

STEP 11.

Once axle is ready, paint truss and axle where bare steel is

exposed to prevent rusting. After paint is dry, reinstall axle breather hose,

electric locker wire, and any other components. Install axle according to

manufacturers specs.

Community Discussion