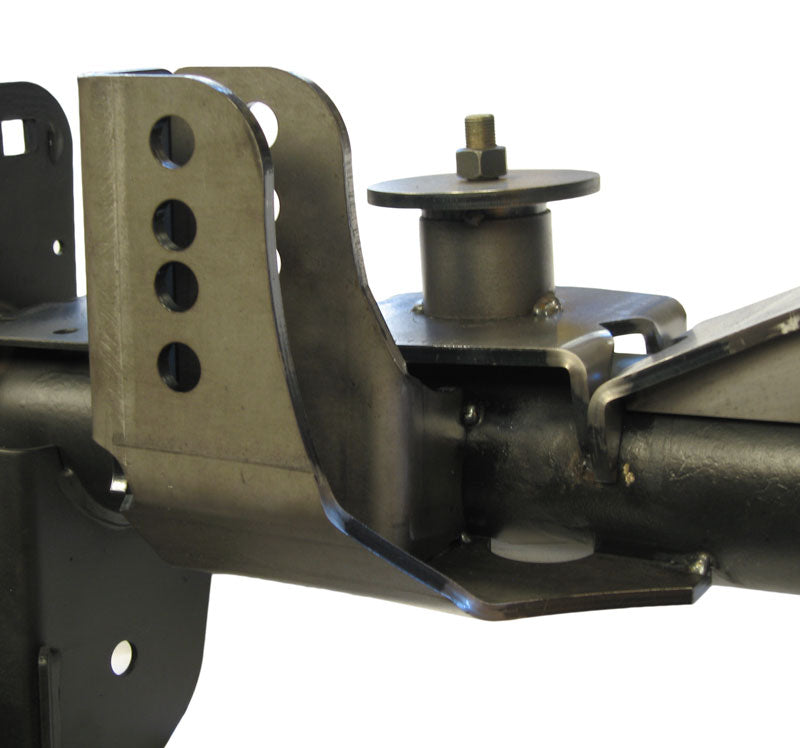

Rear JK Coil Perches and retainers (pair)

- 1/4" steel

- Clockable to any angle for larger lifts

- CNC laser cut and CNC bent for precise fit

- Engineered using 3D scan files

- Made for off-road use

- Made in the USA

Complete your ultimate off-road build with Artec Industires’ Rear Coil Spring Mounts for your vehicle. These mounts perfectly locate your rear coil springs in the factory location for a hassle-free, measure-free swap when used with our rear Axle truss. Our kit includes bottom perches, tubing spacers, flat tube caps, spring retainers, and ½" retainer hardware for both sides of the Axle. Plus, a larger front side and laser-etched guide allow you to locate your spring 1 inch forward for a wheelbase stretch.

Reviews

Install Instructions

This Kit requires Welding and Fabrication skills,

If you are not confident in your abilities please have this product installed

at an Off-road shop.

Tools Required :

Safety Glasses, Jack, Jack Stands, Socket Set,

Wrench set, framing square(X2), Tape measure, drift punch,

Hammer Angle finder, Welder, Welding PPE, Cutting tools

(Example Sawzall, Grinder, Cutting Torch,

Plasma cutter)

Step 1:

Chock the front wheels of the vehicle.

Step 2:

Break the rear lug nuts free

(Do not completely remove the lug nuts.)

Step 3:

Jack up rear of the vehicle and set the frame

securely on jack stands. Keep the Jack under the axle

(You'll need to us this to help control the axle

dropping later on.)

Step 4:

Remove lug nuts and wheels from vehicle.

Step 5:

Unbolt the shocks, rear track bar, Sway bar

end links, and rear driveshaft from the axle housing.

Step 6:

Use the jack to slowly lower the axle down the

coil springs should be able to be pulled out easily

(Keep an eye on the rear brake line make sure it

does not get tight or stretch.)

Step 7:

Use an angle finder to check the angle of you

current spring plates. (Record this number for later on)

Hold a framing square on the center of the

coil spring perches and take a measurement from center to center (Record this number for later also)

Now cut off the current spring plates from the

axle and grind the area smooth to prep for welding.

Step 8:

Install the coil plate, Use the

center to center measurement you took in step 7 to position the coil plates

, Now using the angle finder place it on top

of the coil plate and tilt the coil plates to get the angle you had recorded in

step 7. Then Weld the coil mounts into place.

(The coil plate is offset towards the front of the

vehicle, So make sure the larger part of the plate hangs over the front of the

axle. )

Step 9:

Weld the center tubes to the coil bucket (make sure they are flush with the

bottom of the coil bucket when welding into place.) Tack weld the supplied bolt from the hardware

kit to the bottom of the small round disk. Weld the Small disk on

top of the round tube (with

bolt threads facing up) The big disk will be used in next step .

Step 10:

Paint the coil brackets with some self-etching

primer and paint

Step 11:

Insert the coil springs onto coil

plates, Now slip the large disk inside of coil and have the bolt

from the small tube slip through the hole. Use the nylock nut from

the hardware kit to tighten the round disk. Once this is done you

can raise the axle up into position with the jack.

Step 12:

Install the shocks, Sway bar links , Track bar

and drive shaft onto rear axle. Tighten the bolts finger tight .

(You may need to use a drift punch to help getting

bolts aligned when reinstalling the track bar and shock bolts)

Step 13:

Install the wheels and tighten the lug

nuts (do not torque them

yet) Raise the Vehicle up

off the jack stands with the jack, Remove the Jack stands and lower vehicle

onto the ground .

Step 14:

Torque shock bolts, track bar bolts, sway bar

link bolts, Then lug nuts to factory specs.

After 50 miles or a few trail runs (whichever happens first) check all bolts for proper torque .

Community Discussion