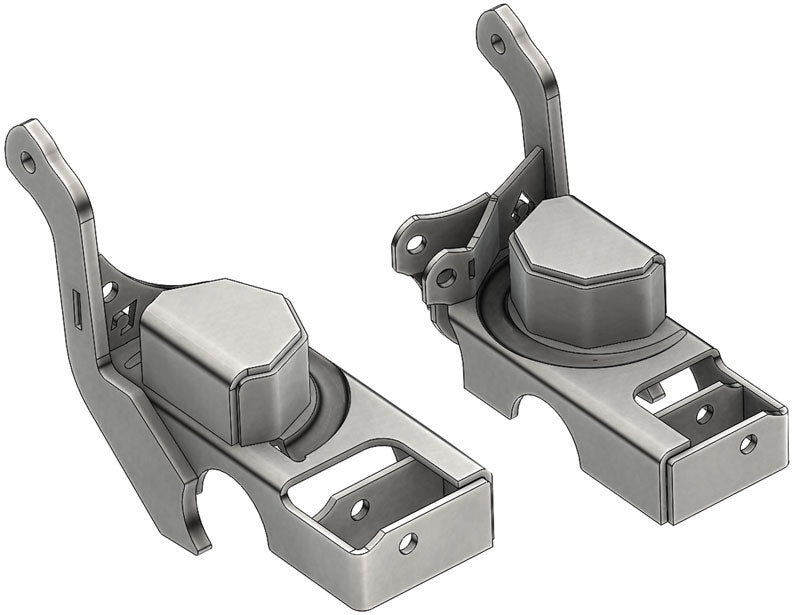

Coil Bracket Replacement for TJ-LJ-XJ-ZJ front axle

- Apex design provides more rigidity than a flat top truss design. Patent Pending

- CNC precision laser cut

- Dimpled holes provide light weight and rigidity

- CNC precision bending ensures perfect fitment

- Hassle-free installation: Reinforced truss – simply drop it in place and start welding

- 3D models from Dana Corp and vehicle OEM for perfect fit and clearance.

- 70% less welding needed than previous designs for less warping, faster turnaround, lower costs

- Contours to both the cast steel differential and FAD (front Axle disconnect)

- Worry-free wheeling for multiple tire sizes on stock axles

Coil Spring Axle Bracket – Front & Shock Axle Bracket Elevate your off-roading experience with Artec Industries’ Front Axle Coil Bracket Replacement. Replace your coil buckets and shock mounts with our heavy-duty bracket for unmatched durability. Our 3/16” thick bracket includes a stamped coil correction, ensuring top performance on any terrain. Don’t compromise on equipment quality. Choose Artec Industries for the ultimate off-roading experience. Made in the USA. Optional Upgrade: Artec Industries’ Lower Control Arm Brackets offer three options – 0 degree, 10 degree, 25 degree angles – for optimal installation flexibility.

Notes : Some changes to factory positions have been altered. The Anti-sway bar bracket hole is 2.75" higher than factory hole to allow for clearance with crossover steering.

Reviews

Install Instructions

Warning:

This Part Requires General

Mechanical Abilities along with Welding

and Fabrication skills to install i f you are not confident in your abilities

Please have this product installed at a Local Off-Road Shop .

Tools Required:

Safety Glasses, Gloves, Wrench set, Socket Set, Torque

wrench, Pliers , Jack, Jack stands(Tall and short) , Wheel chock, Welder,

Cutting tool (Cutoff wheel , Sawzall ) Angle Finder , tape measure ,

Step 1:

Take an inventory of your parts, If you are missing any parts Please contact

Artec Industries Immediately @ (855) 278-3299

M-F 8:30am-5pm MST if it is after those hours Email Sales@artecindustries

with a picture of what you have and packing slip.

Step 2:

Place Wheel chocks at the rear wheels on the vehicle. with the vehicle on the ground break the lug nuts

on the wheels free (Do not fully loosen or remove

them.) Using a jack raise up the

front of the vehicle and place tall jack stands under the frame behind the

lower control arm mounts. and a shorter

set under the axle.

Step 3:

Remove wheels from

vehicle, Remove front drive shaft from

the axle , Remove the brake calipers and

rotors (Set the rotors on a flat surface so they do not

warp), Hang the calipers from the

body with some bungee cords (Do not let the calipers

hang freely from the brake lines this can damage them.)

Step 4:

Remove cotter pins on Tie rods, Then loosen the castle nuts. (Leave the castle

nuts installed by a few threads ! ) Remove

the Steering stabilizer , Grab your Tie

rod Separator, wedge it between the knuckle and the base of the tie rod the hit on the end of the Tie rod separator

with your Big Freaking Hammer until it pops loose. Repeat this on the other

side. Remove the castle nuts and the Drag-link and tie rod should drop off the

Jeep.

Step 5:

Remove the coil spring retainers from the axle, Remove Shocks, sway bar end links, and Track

bar.

Using a jack lower slowly lower the axle to remove the coil

springs. Raise the axle back up and

place jack stands under the axle

Step 6:

Remove upper and lower control arms. Pull the axle out from under the vehicle for

more room to work.

use an angle finder to measure the angle of the coil spring

mounts and use a tape measure to measure the space between the outside of the

Knuckle C and outside edge of the coil

mount (Record these measurements for later)

Step 7:

Coil bracket Assembly. (This bracket

eliminates the bar pin style of lower shock mount in favor of a normal shock

eye using a bolt.) While coil bucket is off axle, take piece 4 and

determine the mounting width of your bottom shock eyelet.( Modifications to the shock bushing may be necessary

depending on your brand.) Bolt

the shock to pieces 1 and 4 and tack weld piece 4 to piece

1. Remove the shock and weld piece 4 fully. Place piece 3 into bottom side of

Part 1 and use your track bar to set the

mounting width to tac weld into place once part 3 is welded into place you can

remove the track bar and fully weld it into position.

Step 8:

Place pieces 9 and 10 on 1. Place your coil spring on piece

1 in the stamped coil relief and use the spring to center pieces 9 and 10.

Remove the spring and tack weld all pieces together.

Step 9:

Using your cutting tool of choice remove the stock could bucket mount and sway

bar end link mounts from the vehicle.

Once they are removed prep the area for welding .

Step 10:

Using the measurements you took in step #6 Place the coil bucket mounts on the axle (TJ3010-1 will go on Passenger side) and rotate until

the degree is matches the one you took in step 6 and tack weld it into place on

the axle

Step 11:

Position the sway bar link onto the axle and slide it up

against the side of the coil bucket, the

flat part of the part 11 mount goes

upright should sit level with the top of the coil bucket tack weld it into position . Place the part 6 tab into the part 11 slot

and tack weld it into place. Now

place your steering damper against part 6 and run a bolt though part 6 and part 8 to Line up and set the spacing for

your damper. tack weld part 8 to the

part 6 and the coil bucket . remove the

steering stabilizer and fully weld parts 11, 6 and 8 to the coil bucket and

repeat the process on the driver side.

Step 12:

On the driver side you will not have part 6 or 8 so you will weld part 7 to the face of the

coil bucket and part 11 to the side of the bucket part 7 will also jig into place on the coil

bucket and sway bar link mount.

Step 13:

Fully weld the coil buckets to the axle once the parts have cooled paint them with a self-etching

primer and paint of your choice

Step 14:

Move the axle back under the Jeep and install the upper and

lower control arms

(A drift punch can help with align the bolt holes, Do not fully tighten

the bolts.)

Step 15:

Install the coil springs and retainers then Raise the axle

onto jack stands.

Step 16:

Install the track bar, shocks, and sway bar end links on to

the axle

(Do not fully tighten the bolts.)

Step 17:

Install the Tie rod

onto the vehicle along with the steering stabilizer.

Torque the, Tie rod ends to 65ftlbs , Steering stabilizer to

55ftlbs

Step 18:

Install the rotors and calipers onto the Jeep torque caliper

bolts to 11ftlbs . Then install the

wheels and tires, tighten lug nuts.

(Do not torque lug nuts yet)

Step 19:

Lower the Jeep off of the Jack stands and onto the

ground. Once the Jeep is on its own

weight.

Torque the lug nuts to 95ft lbs

Torque upper control arm to 55ftlbs

Torque Lower control arm to 85ftlbs

Torque Trackbar to 55ft lbs

Torque Shocks to 20ftlbs

Torque Swaybar links to 75ft lbs.

After 50 miles check all bolts for tightness

and re torque if needed.

Community Discussion